There is a track record of thousands of FMCG items every year that are recalled owing to its packaging seal failures. The integrity of seals are crucial in many industries across packaging, pharmaceuticals and food. Every product comes with a shelf life and it is directly linked to sealed integrity. It impacts shelf life, consumer trust, and product safety. Prior to distribution, the packages are quality checked by experts for preventing any kind of defects in packaging. The presence of a single minor defect can turn out to be detrimental as it exposes contents to contamination, tampering and spoilage. If a single batch is exposed to contamination it could cost urgent consumer advisory.

The conventional way of manual inspection often results in flaws that can result in inconsistency, restricts scalability and increases costs. Here lies the importance of inspection automation. As more FMCG manufacturers are trying to keep pace with the increasing demand of consumers, they are beginning to embrace seal inspection using Computer Vision AI for automating business processes.

In this blogpost, we are going to explore more using Vision AI for FMCG packaging that assists manufacturers actively detecting packaging defects and diminishing the risk of costly product recalls.

Why is it important to inspect seals and closures?

Product seals protect products from any kind of contamination and external damage. It helps to maintain the product’s quality and prevent it from tampering. In the food, beverage and pharmaceuticals industry, tampered packaging can endanger patient safety. The traditional manual checkups often lead to unavoidable faults as it mainly depends on human accuracy.

With the adoption of Computer vision in food manufacturing, seal inspection harnessing Vision AI systems is growing steadily. As per the latest research, it has been found that seal inspection using vision AI is expected to reach US $259 million by 2025. Such automated quality control systems are making a breakthrough in FMCG packaging.

How Seal inspection with vision AI is improving inspection accuracy?

Artificial intelligence utilizes computer vision and machine learning algorithms to find subtle defects. Lets take a look at the major ways in which computer vision AI helps in seal inspection of products packaging.

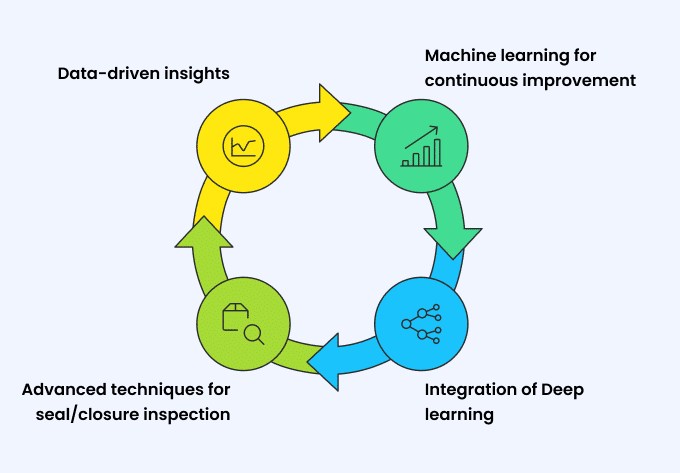

Machine learning for continuous improvement

The AI models in seal integration learn from past defects and advance over time. The advanced speed processing ensures that there are no loopholes. It is important for enterprises that deal with Fast-Moving Consumer Goods (FMCG). Machine learning can be utilized for continuous improvement.

Integration of deep learning

Using deep learning models, the vision AI technology can detect defects in packaging in real-time. AI is one of the highly reliable technologies that reduces false positives. Across major industries, it automates and improves the accuracy of recognizing defects. Deep learning models like Convolutional Neural Networks are trained to recognize and classify different defects in seal images. It can identify subtle defects that can be missed by human inspectors resulting in advanced quality control. Deep learning models are trained on vast datasets of seal images enabling them to learn complex patterns.

Advanced techniques for seal/closure inspection

High-resolution imaging and other sophisticated vision AI patterns enable seal inspection with AI for identifying any kind of minor variations in packaging. Artificial Intelligence can seamlessly identify rare defects.

Data-driven insights

Seal inspection with AI does not collect and analyze data on production trends. It gathers and analyzes data on production trends. It assists manufacturers recognize recurring problems. The AI systems can gather data on different packaging defects and segregate them based on factors like missing seals, uneven sealing, and misalignment. The data helps to improve production efficiency and accomplish greater accuracy. Employing AI for closure and seal inspection is a major investment, however, it is one of the efficient ways that enables human workers to focus on higher-value tasks.

For instance, in the pizza packaging industry, AI-equipped inspection has been ever-increasing for its precision and efficiency. The technology has been able to deliver highly accurate results in comparison to manual inspections.

What are the computer vision benefits of packaging seal inspection?

Better product quality

The automation features of computer vision are capable of detecting defects in package seals with an excellent precision assisting to ensure only products with intact seals reach consumers. It helps to maintain product quality while decreasing customer complaints.

Cost savings

When seal defects are early detected with the help of computer vision, it can avoid product recalls and save manufacturers costs while protecting their brand reputation.

Improved efficiency

The automation of the inspection process through Computer vision in defect detection saves both time and labour costs. These costs are related to the manual inspection process and helps in improving production efficiencies. It decreases the overall labor-costs relating to labor expenses.

Improved data-driven decision making

Computer vision systems offer real-time data enabling manufacturers for making data-driven decisions for process improvement. It results in increased productivity and reduced waste.

How can computer vision assist packaging inspection of seals/closures?

Computer vision helps in the process of packaging inspection in multiple ways. Vision AI is empowered with the potential to detect package seals for leakage or contamination.

Radical leak testing system

Computer vision systems provide an effective leak testing system that can accurately detect package seals for leakage and defects through advanced algorithms and image processing techniques. Vision AI systems can identify even minute leaks that are not detectable by human supervision.

Machine vision

Vision AI provides a revolutionary leak testing system that utilizes machine learning algorithms for analyzing images of package seals. It can be trained to identify different defects or variations in seal quality. It ensures consistent and effective inspection results.

Real-time analysis

With the real-time analysis of package seals, vision AI enables corrective actions and reduces production delays. This ensures keeping defective goods off or store shelves.

Automated inspection

Vision AI systems allow automation of inspection processes for diminishing human operator dependence and at the same time increasing the speed and effectiveness of inspections. The automated inspection allows constant monitoring of package seals so that any glitches can be immediately detected.

Reducing production line footprint

Harnessing a space-efficient computer vision AI technology helps in optimizing factory space and resources effectively increasing productivity and resources.

Protection of brand integrity

It is crucial to maintain product quality through vision AI inspection. Thereby, safeguarding brand reputation fostering customer trust and long-term loyalty.

Final thoughts

Nowadays, manufacturers are embracing computer vision technology for their seal/closure inspection. Having real-time monitoring, automated defect detection and traceability systems, businesses can provide improved consistent quality and optimizes production efficiency. Harnessing cutting-edge algorithms, Computer vision for quality control and machine learning strategies, it can accurately identify package seals/closures for ensuring integrity and preventing contamination to protect customers. Organizations that are using vision AI technology can craft products meeting all the safety and quality standards with confidence. As a leading AI video analytics software development company, Nextbrain creates a detailed analysis of how computer vision technology helped in automating seal inspection of packaging in the manufacturing industry. Ready to get started? Connect with our professionals to know more about AI video analysis.