Workplace safety is a top priority in industries where hazardous energy sources need to be controlled. Lockout Tagout procedures are essential to preventing workplace accidents, and lockout safety padlocks play a crucial role in these safety measures. However, not all padlocks are created equal. To ensure maximum security and compliance, it is essential to choose high-quality lockout safety padlocks with the right features. Below are the top 10 features to look for when selecting lockout safety padlocks.

- Non-Conductive and Durable Material

Lockout padlocks should be made from high-quality, non-conductive materials such as reinforced nylon or thermoplastics. These materials prevent electrical conductivity, reducing the risk of electric shocks and short circuits when working around live electrical components. Additionally, a durable material ensures the padlock can withstand harsh industrial environments, including exposure to chemicals, moisture, and extreme temperatures.

- Key Retention Feature

A high-quality lockout safety padlock should have a key retention feature, meaning the key cannot be removed unless the padlock is in the locked position. This ensures that the padlock is always properly engaged before the key is removed, preventing accidental unlocking or improper use.

- Unique Keying System

To maintain the integrity of lockout procedures, each worker should have a uniquely keyed padlock. High-quality LOTO padlocks offer various keying options, such as:

- Keyed Differently (KD): Each padlock has a unique key to prevent unauthorized access.

- Keyed Alike (KA): Multiple padlocks share the same key, ideal for a single worker managing multiple lockout points.

- Master Key System (MK): A master key can open multiple padlocks, allowing supervisors to access locked equipment in emergencies.

- Grand Master Key System (GMK): A higher-level master key can open multiple sets of locks within an organization. These options provide flexibility while maintaining strict security protocols.

- High-Visibility Color Options

Color-coded padlocks help improve organization and enhance workplace safety. Different colors can be assigned to different departments, employees, or types of machinery, ensuring clear identification of who locked out the equipment. High-quality lockout safety padlocks come in various bright colors, making them easy to identify from a distance.

- Corrosion and Chemical Resistance

Industries such as manufacturing, oil & gas, and chemical plants operate in harsh environments where exposure to moisture, chemicals, and extreme conditions is common. A high-quality LOTO padlock should be resistant to rust, corrosion, and chemical damage to ensure long-term reliability and effectiveness.

- Lightweight and Easy to Use

Lockout safety padlocks should be lightweight yet strong, ensuring ease of use for employees. A well-designed padlock with an ergonomic grip enhances user convenience, allowing workers to lock and unlock equipment effortlessly, even while wearing gloves.

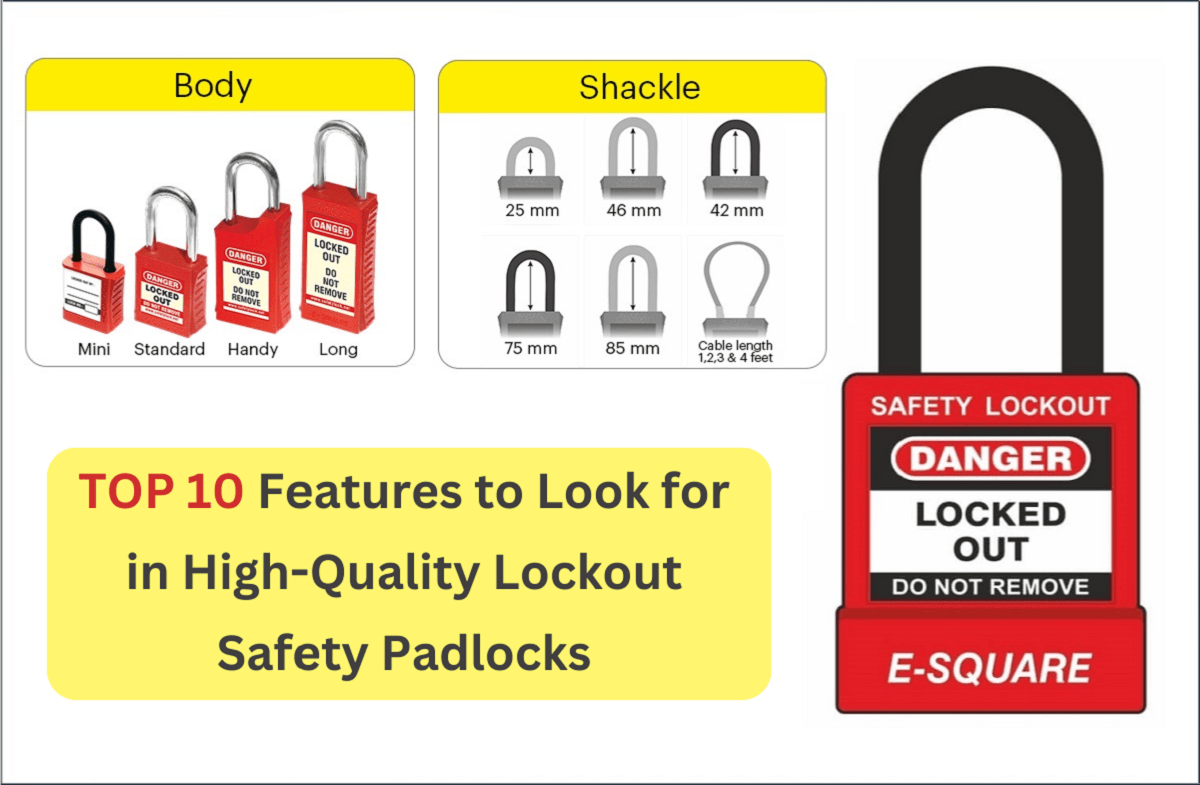

- Shackle Options for Different Applications

Different lockout applications require different shackle materials and sizes. High-quality safety padlocks come with various shackle options, such as:

- Nylon Shackle: Nylon padlock shackle is non-conductive and ideal for electrical lockout applications.

- Steel Shackle: High-strength, best for mechanical and general lockout situations.

- Long-Shackle Options: Provides extra flexibility for locking out multiple energy sources.

- Engraving or Labeling for Identification

To prevent unauthorized removal and enhance accountability, high-quality LOTO padlocks should offer engraving or labeling options. Workers can label their padlocks with names, department details, or specific lockout instructions to ensure proper identification and compliance with safety protocols.

- Compliance with Safety Standards

A lockout safety padlock must meet international safety standards such as OSHA 29 CFR 1910.147, ANSI Z244.1, and other relevant industry regulations. Compliance ensures that the padlock is tested and certified for workplace safety applications, reducing liability risks.

- Tamper-Proof Design

Lockout padlocks should be designed to resist tampering, unauthorized removal, or forced entry. Features such as reinforced shackles, high-security locking mechanisms, and robust body construction enhance the padlock’s resistance to breakage and unauthorized access.