With the demand for diversified designs and the wide application of new materials, plastic materials are favored by designers and users because of their unique characteristics. There are many types of plastic materials, with obvious characteristics and wide applications, acrylic materials are undoubtedly the ones.

Ⅰ. Thermoforming

With the continuous development of science and technology, the manufacturing industry is also constantly innovating and progressing. Among them, thermoforming process, as an emerging manufacturing technology, is gradually becoming a new trend in the future manufacturing industry.

Thermoforming is divided into thin gauge thermoforming and heavy gauge thermoforming according to the thickness of the sheets.

Thermoforming is a plastic processing technology. The main principle is to heat a flat hard plastic sheet to soften it, then use vacuum to adsorb it to the surface of the mold, and then cool it into shape. It is widely used in plastic packaging, lighting, advertising, decoration and other industries.

Heavy gauge thermoforming refers to the use of materials with a thickness exceeding 2mm, which cannot be vacuum formed on fully automatic tools. A semi-automatic vacuum forming machine dedicated to thick gauge thermoforming must be used for processing and production.

To optimize the sheet forming process, it is crucial to consider various factors. Begin by carefully managing stress concentration heat sheet, ensuring that ambient air temperature is controlled. Achieve uniform temperature distribution across the sheet, paying particular attention to the sheet interior’s cooling time. Use a proper mold covering to maintain forming temperature low. Employ a blowing mold consists of optical light sensors for precise monitoring. Alternatively, a jig or soft material can be utilized to enhance the cooling process. Implementing a horizontal heating system further contributes to the overall efficiency and effectiveness of the sheet forming operation.

Vacuum forming can be used for product design and manufacturing of rear-projection TV back covers, displays, medical equipment, textile machinery, automotive accessories, and product design and manufacturing in precision electronics, medical equipment, and cosmetics industries.

The main advantage of pressure forming is that it can produce complex shapes and sizes, while also providing supporting services during the manufacturing process, such as printing and assembly, to meet vacuum forming requires of different customers.

Ⅱ. Acrylic Sheet

Acrylic

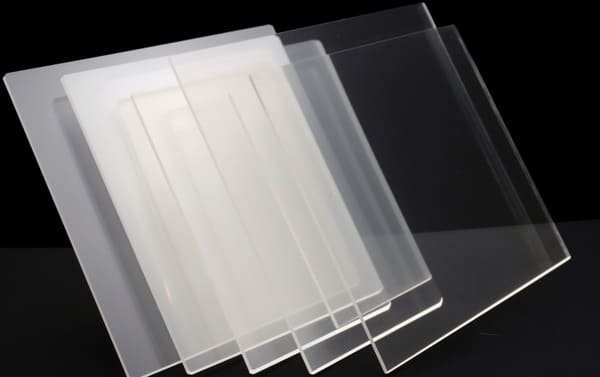

Acrylic (PMMA) particles are colorless or transparent material with a specific gravity of 1.19 g/cm3 and low surface hardness. They are easily scratched by hard objects and difficult to catch fire. The melting point of PMMA is about 130–140°C, which is much lower than the high temperature of glass, which is about 1000 degrees.

The panel is coated with a high concentration of ultraviolet absorber. Acrylic has high transparency, can be weathered for a long time, never fade, has a service life of 5 to 8 years, and has good light transmittance, up to 93%, with excellent light transmittance and light soft.

Acrylic sheet is a plexiglass processed through a special process. It has strong hardness, good material, radiation protection, and good light absorption effect. With the development and widespread application of optical technology, it has gradually been widely used in industrial manufacturing and modern home life. middle. Moreover, acrylic materials have large sales volume and high recognition in the market.

PMMA has the advantages of being light, cheap, and easy to form. Its forming methods include casting, injection molding, machining, vacuum forming, etc. Injection molding, in particular, can be produced in large quantities with simple process and low cost. Therefore, its application is becoming more and more widespread, and it is widely used in instrument parts, automobile lights, optical lenses, transparent pipes, etc.

Why is Acrylic Sheet Suitable for Thermoforming?

Appearance

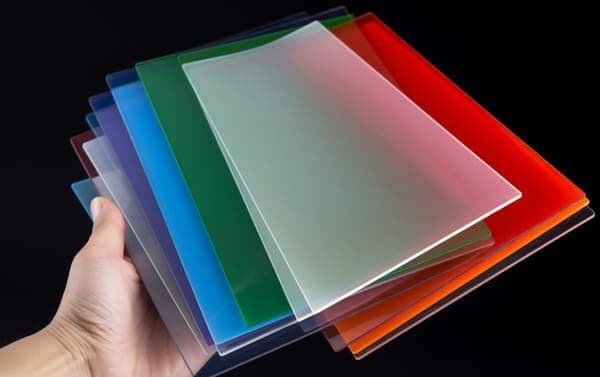

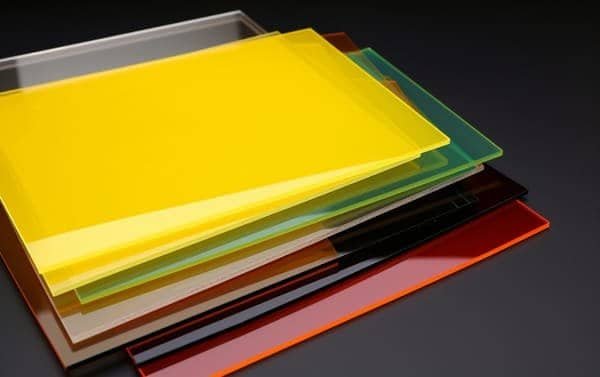

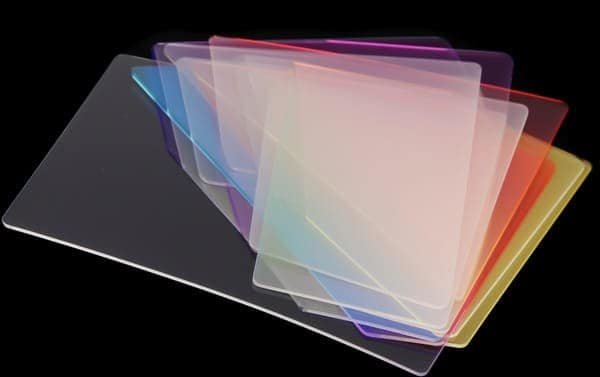

From the appearance point of view, acrylic sheets have the same transparency as crystal, with good light transmission effect, which can reach more than 93%. In the design and manufacturing process, many different colors can be customized according to requirements.

The dye effect is good. After a long period of There is no possibility of color fading after use. Only with good quality can it be widely promoted and used in the decoration process.

Good Processing Performance

It has excellent heat resistance. Generally speaking, the surface of its acrylic sheet has the advantage of very good resistance to high temperatures after encountering high temperatures. Of course, for different size ranges, they all need to be processed before they can be installed.

Its processing performance is relatively strong, and the quality and performance are the same as before processing. At the same time, it has good toughness and no defects will appear during the processing, the outdoor service life is about 5-10 years, and the color remains as new during use.

Production Process

In terms of the production process of acrylic sheets, there are mainly two types: casting type and extrusion type. The hardness and toughness of the sheet are improved through hot processing technology. This is why at the current stage, acrylic panels installed outdoors will not have any quality problems after a long period of weathering.

Therefore, the emergence of this new sheet material can have unique technical advantages from this process and form its own characteristics at the current stage.

Cast Plate: Higher molecular weight, excellent stiffness, strength and excellent chemical resistance. Therefore, it is more suitable for processing large-sized sign plaques, and the softening process takes a relatively long time.

This sheet is characterized by small batch processing, unmatched flexibility in color system and surface texture effects by other products, and complete product specifications, suitable for different needs.

Extruded plate: Compared with cast plate, extruded plate has lower molecular weight and weaker mechanical properties, but has higher flexibility, which is beneficial to bending and thermoforming processing, and its softening time is shorter. When processing larger-sized sheets, it is beneficial to various rapid vacuum forming.

At the same time, the thickness tolerance of extruded plates is smaller than that of cast plates. Since extruded boards are produced automatically in large batches, the colors and specifications are difficult to adjust, so the diversity of product specifications is subject to certain restrictions.

Translucency

In terms of appearance light transmission effect, there are mainly types such as transparent, translucent, milky white, etc. The colors are different, and the surface effects will also be different, and the visual impact is very strong.

Excellent Material

Acrylic sheet is a new green and environmentally friendly material in the 21st century. It has a high recycling rate and can be reused to make simple sheets. It has strong light transmittance. These characteristics make it play a key role in the decoration process.

Ⅲ. Application of Acrylic Thermoforming Products

In terms of engraving, decoration, handicraft production, advertising signs, light boxes, etc. PMMA has the advantages of being light, cheap, and easy to form.

Therefore, its application is becoming more and more widespread, and it is widely used in instrument parts, automobile lights, optical lenses, transparent pipes, etc.

In construction, it is mainly used in lighting bodies, roofs, sheds, stairs and interior wall panels. The application of acrylic in lighting lampshades and automotive lamps on highways and high-end roads is also quite rapid.

With the construction of hotels, guesthouses and high-end residences in big cities, lighting bodies have developed rapidly. Lighting bodies made of extruded plexiglass panels have the characteristics of high overall structural strength, light weight, high light transmittance and good safety performance. Compared with inorganic glass lighting devices, it has great advantages.

In terms of sanitary ware, acrylic can be used to make bathtubs, washbasins, dressing tables and other products. Acrylic bathtubs have been widely used due to their luxurious appearance, depth, easy cleaning, high strength, light weight and comfortable use.

Acrylic is the best new material for manufacturing sanitary ware after ceramics. Compared with traditional ceramic materials, in addition to its unparalleled high brightness, acrylic also has the following advantages:

It has good toughness and is not easy to be damaged, it has strong repairability. Just use soft foam and a little toothpaste to wipe the sanitary ware as new.

The texture is soft and does not feel cold and biting in winter.

The colors are bright and can meet the individual pursuits of different tastes.

Using acrylic to make basins, bathtubs, and toilets is not only exquisite in style and durable, but also environmentally friendly. Its radiation is almost the same as the radiation of the human body’s own bones.

Acrylic can be made into various fashionable products, such as leather bags, waist chains, watches, high heels, heels, hair accessories, brooches, bracelets, buttons, earrings, necklaces, rings, pendants, photo frames, etc. There are many types and unlimited development space for continuation.

At the same time, acrylic material has high processing plasticity and good surface hardness and transparent luster. It is often used by designers to match with various materials in the design of various exquisite containers to add texture and practicality to the containers, such as lipsticks and Delicate containers such as chemicals, and other daily necessities such as massagers, jewelry boxes, fans, etc.

Taking advantage of the cool feeling of acrylic material and combining it with creative design, acrylic material is perfectly presented in a variety of popular boutiques.

Acrylic thermoformed door panel series: European style, Chinese style doors, door frames, dado panels, ceilings, gussets, etc.

Acrylic thermoformed curtain boxes, window sill panels, window covers, etc.

Acrylic thermoformed furniture series: desktops, benches, countertops, shelves, kitchens (bookcases, wardrobes), etc.

Acrylic thermoformed series production of various speakers.

Processing and production of acrylic thermoformed vehicles and special-shaped decorative products for boats.

Ⅳ. Advantages of Thermoformed Acrylic Products

Transparency

Colorless and transparent organic glass sheet with a light transmittance of over 92%.

Excellent Weather Resistance

It has strong adaptability to the natural environment. Even if it is exposed to sunlight, wind and rain for a long time, its performance will not change. It has good anti-aging performance and can be used outdoors with confidence.

Good Processing Performance

Suitable for both machining and vacuum forming, acrylic panels can be dyed, and the surface can be painted, screen-printed or vacuum coated.

Excellent Comprehensive Performance

Acrylic boards come in a wide variety of colors, and have extremely excellent comprehensive properties, providing designers with a variety of choices. Acrylic boards can be dyed, and the surface can be spray-painted, screen-printed or vacuum coated.

Non-toxic

It is harmless even if it comes into contact with people for a long time, and the gas generated when burned does not produce toxic gas.

Made of PMMA acrylic thermoforming, it has the characteristics of good light transmittance, bright and clean exterior and interior, environmental protection, and can be painted. The color can be changed to produce products of different specifications and shapes according to customer requirements.

Mainly used in plastic transparent covers of lampshades, observation instrument covers, leisure furniture hammocks, organic handicrafts, bank signboards, advertising light boxes, etc.

Ⅴ. Precautions for Acrylic Thermoforming Production

General acrylic will undergo thermal deformation at about 100 degrees Celsius, so you must pay attention to this temperature when using it, and if it is to be used continuously, the temperature cannot be higher than 90 degrees.

When acrylic thermoformed products become blurry or unclean due to slight scratches or dust adsorption due to static electricity, you can use 1% soapy water to wipe them clean with a soft rag.

The hardness of the thermoformed surface is comparable to that of aluminum, so care should be taken to avoid scratching the surface when using or processing acrylic. If it is accidentally scratched, it will need to be restored by polishing.

When installing acrylic products, thermal expansion and contraction must be taken into consideration, and there must be a space for expansion and contraction during assembly.

If the preliminary processing work is not done well, the acrylic thermoformed product will also be deformed at the moment of demoulding, and the quality of the deformed product will inevitably be affected. In order to avoid similar problems from happening again, we must develop corresponding solutions to this problem.

In order to prevent deformation after pressure forming is demolded, the operator is first required to check the temperature of the cooling water, and at the same time adjust the water volume of the nozzle to meet the specified range. Secondly, the wind direction at each location must be adjusted to find the most suitable forming pressure for acrylic thermoforming production.

In addition, when demoulding, try to use the pressure of vibrating the upper mold to force smooth demoulding. If the air volume at the bottom can be appropriately increased, it will also be helpful to ensure the quality of acrylic thermoformed products. If these cannot solve the problem, the only way to overcome the deformation problem is to re-make the upper mold.

Conclusion

With the continuous advancement of social science and technology and the continuous improvement of process technology, acrylic thermoforming will have broader market prospects and application prospects in the future. Its future development trends include the following aspects:

1. Continuous improvement of creativity: As people pay more and more attention to personalization, acrylic thermoforming will use more creativity to create more unique products through different processes and materials.

2. More environmentally friendly and energy-saving: When making acrylic thermoforming products, low-carbon, environmentally friendly, and energy-saving methods will be increasingly used to achieve a greener production environment.

3. Upgrading of materials: As people pay more and more attention to health and environmental protection, acrylic blister materials will increasingly use healthy, environmentally friendly and safe materials, and improve the performance indicators of the materials through technical means.